Liquid Defoamers

Product Details:

- HS Code 3824

- Solubility Water

- Form Other

- Smell Other

- Taste Other

- Chemical Name SULPHONATED CASTOR OIL

- Grade Industrial Grade

- Click to View more

Liquid Defoamers Price And Quantity

- 25 Metric Ton

- 783.00 - 785.00 USD ($)/Metric Ton

- 784 USD ($)/Metric Ton

Liquid Defoamers Product Specifications

- Other

- Defoamer

- Liquid

- Other

- wood pulp, paper, paint, industrial wastewater treatment, food processing, oil drilling, machine tool industry, oils cutting tools, hydraulics

- Water

- 3824

- Other

- Industrial Grade

- SULPHONATED CASTOR OIL

Liquid Defoamers Trade Information

- Letter of Credit (L/C) Cash Advance (CA)

- 20000 Metric Ton Per Month

- 15 Days

- Yes

- Australia North America Eastern Europe Western Europe Africa Middle East South America Asia Central America

Product Description

Liquid defoamers are chemical compositions intended to minimise or completely eradicate foam generation in a variety of industrial processes and applications. They are also known as antifoaming agents or foam control agents. They are offered in liquid form for simplicity in handling and use.

Following are some essentials regarding liquid defoamers:

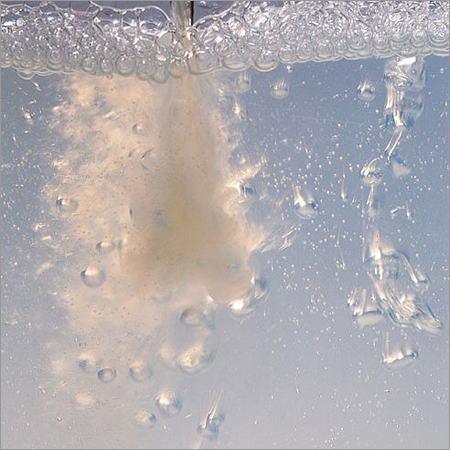

1. Foam Formation: Foam is produced when gas bubbles are caught in a liquid or solid object. In a variety of industrial processes, foam can form as a result of agitation, aeration, surfactant activity, or chemical reactions.

2. Liquid defoamers are designed to interfere with and inhibit the development of foam. They destabilise foam bubbles, lessen surface tension, and make it easier for trapped gas to escape. This aids in removing foam or stopping it from forming.

3. The active ingredients in liquid defoamers can be a mixture of silicone-based substances, mineral oils, fatty acids, esters, alcohols, or other chemical additions. The application and the kind of foam under consideration will determine the precise composition.

4. Liquid defoamers are utilised in a variety of processes and industries, such as the following:

a. Chemical processing: Foam generation can impair process efficiency and have an impact on product quality. Liquid defoamers are employed in this industry.

b. Food and Beverage: Liquid defoamers are used in the food and beverage business while processing a variety of goods, including dairy, brewing, fruit juice, and fermentation operations.

c. Pulp and Paper: To reduce foam during procedures like pulping, bleaching, and paper coating, liquid defoamers are used in the manufacture of pulp and paper.

d. Wastewater Treatment: To reduce foam produced by biological or chemical processes, liquid defoamers are utilised in wastewater treatment facilities.

e. Paints and Coatings: To avoid foam during the manufacture, application, and drying processes, liquid defoamers are employed in paint and coating compositions.

f. Textile Processing: To minimise foam formation and promote consistent dye penetration, liquid defoamers are used in the dyeing and finishing processes of textiles.

5. Dosage and Use: Where foam is an issue, liquid defoamers are normally supplied directly to the system. The dosage is determined by how severe the foam generation is and the application's particulars. In accordance with the recommendations for their products, manufacturers offer recommendations for the best dosage amounts.

6. Safety Considerations: Follow the manufacturer's instructions and safety precautions when handling and applying liquid defoamers. Some liquid defoamers could include chemicals that should be handled with sufficient ventilation and personal protection gear.

In many industrial processes, liquid defoamers provide a practical way to manage foam, enhancing productivity, product quality, and worker safety. Their use can greatly lessen foam-related problems in a variety of sectors because they are flexible items that are designed for particular uses.

Features:

- Free from impurities

- Precise pH value

- Balanced composition

- Insoluble in the foaming medium

Product Specifications:

|

Description |

Specification |

|

Assay by purity |

10.00% |

|

Appearance |

White Colour |

|

Effect on material |

8-10 Second |

Packing:

- 50 Kg HDPE Carboys

Application

Used in chemical industries like:

- Pharmaceuticals

- Textiles

- Dyes

- Pigments

- Petrochemicals

- paper industries

- Colours

- Agro products

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Chemicals' category

|

RADHE ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese